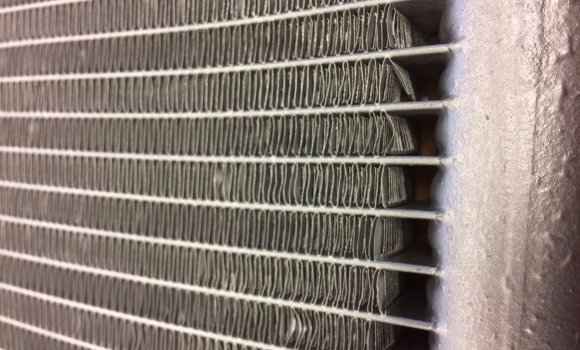

Microchannel Coating

The Micro Channel Heat Exchanger (MCHE) development originates from the automotive industry where it has been used since more than twenty years now. They have however only recently been introduced to the HVAC&R industry. Some of the big advantages are that they are lighter, more efficient and they lower the required refrigerant volume. Another advantage of an MCHE coil is that it’s made out of aluminium only. This makes it less vulnerable to galvanic corrosion (caused by combining dissimilar metals) than the traditional RTPF coils. The MCHE coils not only bring the above mentioned advantages , they also bring with them extra challenges. In corrosive environments, not only the fins will corrode but also the aluminum tubes are at risk.

Blygold PoluAl MC: flexible coating & flexible application process

Coating flexibility

Blygold PoluAL MC is a flexible coating. Even after thermal cycle testing the coating is able to withstand fin bending without risk of cracking or delaminating. Another major advantage of this coating flexibility is that flat micro channel coils can be bent after the coating has been applied. Tests have shown that the coating is still in perfect condition on the bended areas.

Application flexibility

PoluAl MC is applied through Blygold’s special spray techniques. This makes the application very flexible. It can be applied to any size of micro channel heat exchanger without any restriction. When coils are already bent they can also be treated with PoluAl MC.

HVAC corrosion protection

Blygold has developed pioneering new coatings specifically for HVAC corrosion protection. From the very beginning Blygold has always focused on corrosion protection for heat exchangers, which are vulnerable to severe corrosion because of their construction with dissimilar metals and pollution from air circulation.

The success of these protective corrosion products derives from the unique application method including a thin layer, high UV and chemical resistance properties. These reputable products are renowned in the air conditioning business worldwide. Blygold are proud of their extraordinary success stories and our honoured to have worked on ambitious projects like the cruise ship Queen Mary 2, Palm Island Jumeirah and London Heathrow Airport.

The Advantages

- Preserves high efficiency of micro channel HX

- Prevents early micro channel HX failure

- Heat conductive protective layer

- Improved water release properties

- Highly flexible for coil bending

- Reflective pigment prevents sun radiation absorption

- 11.000 hour salt spray test ASTM B117

Without Blygold

With Blygold