Blygold Corrosion Protection

Blygold is the specialist on corrosion protective, energy saving and lifetime extending products and services for HVAC/R equipment. With over 45 years of experience, we are a respected and liable partner for Building owners, Facility Managers, Contractors, Manufacturers and end-users dealing with HVAC/R equipment in corrosive environments. We operate a global network that is represented by over 75 companies in more than 60 countries worldwide. Our global headquarter is located in the Netherlands and we have regional headquarters in the USA (Florida) and Australia (Queensland) from where we support our valued partners.

Blygold has built a global brand that is recognized and acknowledged for its high-quality services, by continuously investing in innovation and product development. By working through a network of dedicated, trained and professional Blygold businesses we can ensure the same high quality of our services, products and after service, no matter where you are in the world.

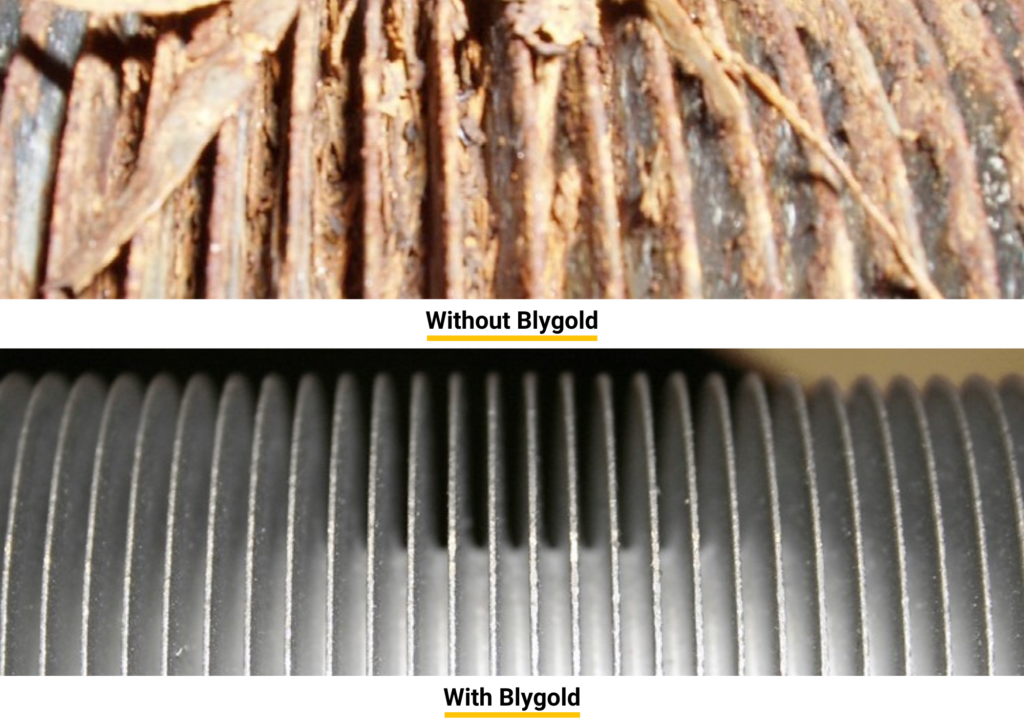

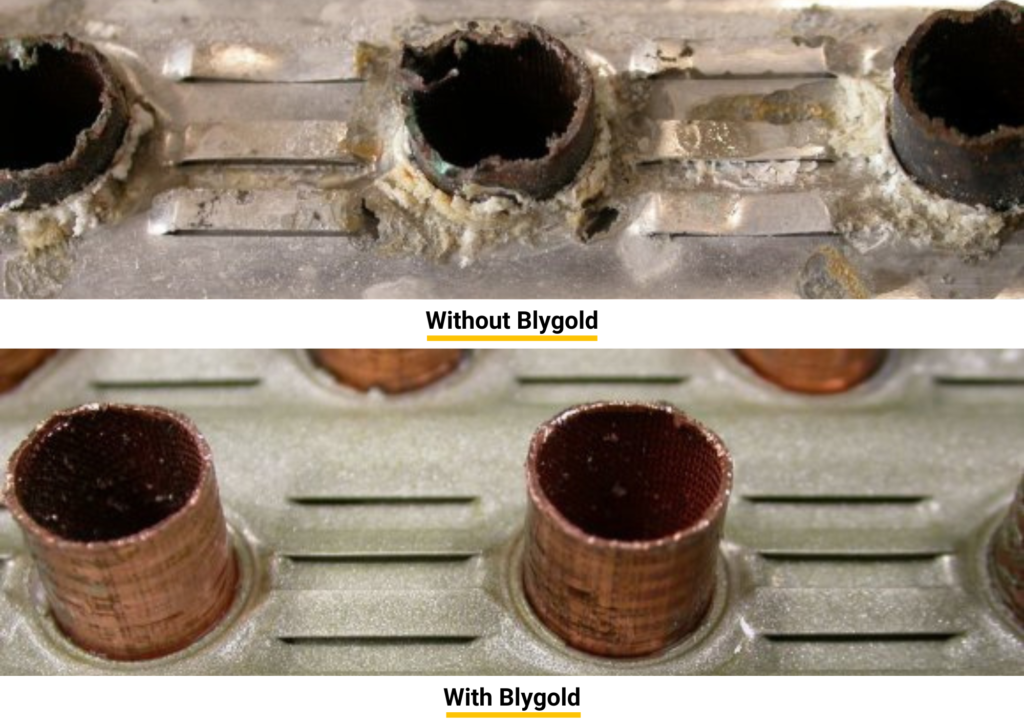

Corrosion Protection

Blygold helps to corrosion protect your HVAC equipment against corrosion and efficiency improvement coatings for centrifugal pumps to prevent high energy bills, maintenance costs and early replacement. By choosing Blygold you will ensure your equipment to be reliable, efficient and operational in optimal conditions.

- HVAC Coil Coating (RTPF)

- Microchannel Coationg

- Finned Tube Coating

- Tube Sheet & Waterbox Cladding

- Cabinet & Casing Coating

- Refurbishment & Rejuvenation

- Pump Coatings for Efficiency Improvement

Corrosion

Causes

- Salts

- Humidity

- Wind

- Carbon monoxides

- Carbon dioxides

- Hydrocarbons

- Sulfur dioxide

- Nitrogen oxides

The Advantages

- Coating application after coil manufacturing

- Cutting edge protection

- No coating between fin collar & tube

- Service on-site possibility

- Touch up or repair possible

- UV resistance

- Limited capacity loss

- Limited hydrophobic surface properties

- Worldwide application possible

- Copper tubing protection

The Applications

- Data Centers

- Transport & Construction

- Airports

- Museums

- Hotels & Office Buildings

- Powerplants

- Sport Facilities

- Offshore & Marine

- Hospitals

- Factory

HVAC Corrosion Protection

Finned Tube Corrosion Protection